The ice cream cone is more than just a vehicle for serving ice cream; it is a quintessential element that enhances complete ice cream involvement and adds shape to the consumption of ice cream.

The ice cream cone holds significant importance within the ice cream world due to its historical significance, practical benefits, economic impact, and adaptability to trends. Here’s a detailed exploration of its importance:

Invented in the early 20th century, the ice cream cone transformed the consumption of ice cream, becoming a popular choice at fairs, beaches, and city streets. Over time, it evolved into a cultural icon, symbolizing childhood joy, summer fun, and indulgence. Its presence in popular culture, advertising, and media reinforces its iconic status.

Serving as a convenient carrier, the cone provides an edible container for ice cream, reducing the need for disposable bowls and spoons. This eco-friendly aspect makes it a preferred option over plastic or paper alternatives. Additionally, its portability makes it ideal for outdoor events and casual dining.

The introduction of the ice cream cone drove significant growth in the industry, expanding sales and leading to the establishment of ice cream parlours and street vendors. Cones offer a platform for product differentiation, with various types available (wafer, sugar, waffle, and specialty cones), allowing shops to cater to diverse tastes and preferences.

The ice cream cone enhances the overall ice cream experience by providing a textural contrast between the crunchiness of the cone and the creaminess of the ice cream. Specialty cones, such as chocolate-dipped or flavoured varieties, add further layers of flavour. Moreover, modern customization options allow customers to tailor their treats to their preferences, increasing satisfaction and fostering repeat business.

Recognizing the significance of ice cream cones, ICT has reached out to several popular cone manufacturers to gather their insights. This effort aims to provide our readers with a broader understanding of the ice cream industry.

From the Experts:

Kishan Bhalodiya, MD, Ether Corporation, Ahmedabad

Sundeep Pamnani, Managing Partner, Wafer Magic by Gemni, Hyderabad

Raja PS, Founder, MD-Mano Products, Madhurai

Manoj Sivaya, Topnotch Foods LLP, Anand, Gujarat

Sanjeev Pamnani, Managing Partner, Gemini Food Equipment (Machinery), Hyderabad

Siddhartha Karnany, Director, S M Icecream Mart

What sizes do your ice cream cones come in, and how do you choose the right size for different needs or tastes?

Offering a exact reply, Kishan Bhalodiya made the statement that waffle cones have long been celebrated as the ideal accompaniment to ice cream. Initially, when they were invented, cones lacked variety, but their natural blend of ingredients provided a sweet and perfect complement to a wide range of ice cream flavours. Over time, as the culinary world evolved, waffle cones underwent further refinement. They now come in various sizes, shapes, and flavours. Waffle cones themselves have acquired delightful enhancements, including sprinkles, chocolate coating, and chocolate chips.

“At Ether Corporation, we manufacture two types of cones specifically designed for ice cream. These cones are commonly used in supermarket ice cream products. Both cone types share a 23-degree angle at the tip but differ in size. The larger cones measure 110 mm in length, while the smaller variation is 95 mm long. Interestingly, neither cone type is tied to a specific ice cream flavour; they can be paired with a variety of flavours based on the needs of the manufacturing business.

“The primary factor determining the preferred cone size is the price of the product. For more affordable ice cream offerings, smaller cones are preferred. Conversely, when the product commands a higher price, larger cones are the go-to choose”, Kishan completed his reply.

According to Sundeep Pamnani, the origin of the sugar cone can be traced back to the early 20th century, around the same time as the invention of the ice cream cone itself. The ice cream cone is believed to have been popularized at the 1904 World’s Fair in St. Louis, Missouri. The sugar cone emerged as a variation of the original wafer cone, driven by the desire for a sturdier cone that could better withstand melting ice cream without becoming soggy. Over time, the sugar cone became a staple in ice cream parlours. Today, sugar cones are a beloved part of the ice cream experience, appreciated for their ability to complement and enhance the flavour and texture of the ice cream they hold.

Sundeep went on to explain, “Choosing the right ice cream cone size is crucial, as it varies according to the different needs and tastes of our consumers. During the COVID-19 pandemic, the industry faced a surge in raw material prices. To maintain the maximum retail price (MRP) on packaging materials, manufacturers were compelled to reduce the sizes of ice cream cones. This adjustment helped manage costs while continuing to meet consumer demand”.

Here are the standard sizes available:

• 46 x 10 mm: This was the standard size before the price surge, typically holding 80-100 ml of ice cream.

• 41 x 95 mm: This is the new size that has gained popularity, holding around 50 ml of ice cream.

• 35 x 85 mm: This smaller size is now gaining popularity in highly competitive areas like West Bengal, holding around

40 ml of ice cream.

“At Wafer Magic, we offer all the above sizes to meet various needs and preferences”, added Sundeep.

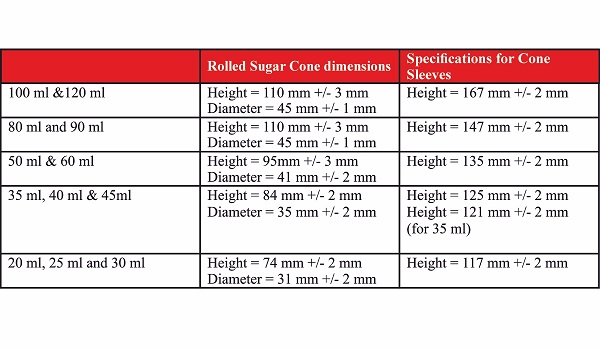

With reference to the question, Raja PS neatly presented a chart mentioning the different sizes of ice cream cones manufactured by them.

These dimensions are highly demanded in the ice cream market.

Manoj Sivaya, too, offered his feedback. “Our ice cream cones are available in a range of sizes: 75 mm, 85 mm, 95 mm, and 110 mm. The flavour of our cones remains consistent, unless a customer specifically requests a different variety, such as a dual cone, vanilla cone, or chocolate cone. We customize the sizes of our cones to meet the specific preferences and requirements of our customers”.

Siddhartha says, “At SM Mart, our ice cream cones come in four sizes:

Mini (2-3 inches): Perfect for small children, samples, and events.

Standard (4-5 inches): Ideal for everyday single servings.

Large (6-7 inches): Great for multiple scoops and larger portions.

Jumbo (8 inches+): Best for sharing and special occasions.

Choosing the Right Size: We offer both molded and rolled sugar cones in various sizes to suit your ice cream packaging needs.

Ice Cream Type: Match the cone size to the density of the ice cream.

Audience: Consider the preferences of children vs. adults and health-conscious consumers.

Occasion: Select the size based on events or regular use.

Portion & Cost: Opt for smaller sizes for portion control and savings, and larger sizes for indulgence.”

When it comes to making cones, do you find that customers generally prefer machine-made or handmade cones?

“Over time, various cone designs have emerged to cater to different scenarios. For instance, if the ice cream is sold at a parlour or factory outlet where cones are hand-filled with flavours chosen by customers, handmade cones are the preferred option”, coined Kishan. “These handmade cones have a longer length and a broader angle, resulting in a wider opening. This facilitates easy filling by parlour workers, allowing them to serve customers promptly. In contrast, ice cream cones destined for supermarkets are machine-filled and specifically designed for slightly narrower openings. The precise dimensions are crucial for compatibility with ice cream filling machines. Handmade cones, with their greater variation in dimensions, are not suitable for this purpose”.

Sundeep notes that customer preferences frequently determine whether to purchase cones that are manufactured by hand or by machine. When consuming ice cream, consumers may have different preferences for different types of cones depending on their surroundings and circumstances.

Seeing the sides of the topic, Sundeep says that although they have a lovely handmade aspect, homemade cones are not always consistently baked. This unpredictability may lead to varying moisture content, which would reduce quality and shorten shelf life. However, sugar cones that are manufactured by machines provide a dependable substitute. These cones, which are made with automated procedures, have a longer shelf life and consistently high quality”.

Talking about his company, Sundeep explains, “By using cutting-edge equipment, such as the Gemni brand Rolled Sugar Cone Machines, correct baking with temperature control and timing is ensured, producing low-moisture cones with a minimum six-month shelf life. Customers typically choose machine-made cones because of these benefits, as well as the products’ dependability, high quality, and long shelf life”.

Giving precise information about Mano Product enterprise, Raja PS replied, “We cater to wholesale ice cream manufacturers who typically prefer machine-made cones over those produced for retail ice cream shops. Consequently, to meet high demand, we focus exclusively on producing machine-made cones in large quantities”.

Manoj also opines the same. “Due to the high demand for cones in the market, handmade cones cannot fulfill the required volume, making machine-made cones the only viable option for large-scale production. Handmade cones are typically reserved for standalone parlours that prioritize artisanal presentation and serve ice cream in scoops, offering a unique experience for customers seeking a more traditional touch”.

Siddhartha says, “If the customer is visiting an ice cream parlour, they typically prefer handmade waffle cones for their unique texture and flavour. However, an ice cream manufacturer would always opt for machine-made cones due to their consistency, efficiency, and ability to meet high-volume demands.”

Nowadays, we find innovative and unique flavour- fusions in cones. How do you ensure that ice cream and cone flavours complement each other and enhance the overall ice cream experience?

Kishan’s insights are truly insightful! The idea that the colour and flavour of the cone should align with the ice cream it accompanies makes perfect sense. It creates a harmonious and cohesive experience for the consumer, where every element, from the cone to the ice cream, complements and enhances each other.

This attention to detail not only adds aesthetic appeal but also elevates the overall flavour profile of the ice cream. When the cone and ice cream flavours are aligned, it creates a more immersive and satisfying eating experience, where every bite is a delight for the senses.

Manufacturers’ development of flavour-specific cones demonstrates their commitment to innovation and enhancing consumer enjoyment. It’s a testament to the creativity and ingenuity within the food industry, which is constantly striving to improve and refine the products we love. For example:

• Dark chocolate cones pair perfectly with chocolate-flavoured ice cream.

• Pink cones complement strawberry ice cream.

• Plain beige cones harmonize with classic vanilla.

Most flavour-enhancing cones use the same base ingredients as plain cones but incorporate complementary food colouring. Natural additives like activated charcoal create darker hues, quoted Kishan.

“Ensuring ice cream and cone flavours complement each other is crucial, especially given that the most popular ice cream flavours—Vanilla, Butterscotch, Chocolate, Strawberry, and Dry Fruits—comprise 80% of the ice cream market sales. These popular flavours are exceptionally complemented by the flavour of sugar cones”. Sundeep articulated that the natural sweetness and crunch of the sugar cone provide a perfect balance to a wide variety of ice cream flavours, making the combination more enjoyable and satisfying.

Sundeep also cited that while consumers often focus on their preferred ice cream flavours, the quality and choice of cone play a significant role in enhancing the overall ice cream experience. The texture and subtle sweetness of sugar cones can elevate the flavour of the ice cream, adding a delightful crunch that contrasts beautifully with the creamy texture of the ice cream. This synergy between the cone and the ice cream creates a more enjoyable and satisfying treat, highlighting the importance of both elements in creating the perfect ice cream experience.

Raja PS mentioned, “Our machines have the capacity to produce cones in a variety of flavour combinations, such as red velvet and chocolate. We serve customers throughout South India, where tastes and preferences vary significantly across regions. To best meet our customers’ needs, we tailor our offerings to the distinct tastes and preferences of each area”.

Manoj asserted that they work closely with ice cream manufacturers to ensure that their cones complement and enhance the flavours and textures of their unique creations, offering a seamless fusion of taste and presentation for their customers. This collaboration allows for a meticulous pairing of cone and ice cream, ensuring that each element enhances the other.

“By aligning the characteristics of the cones with the distinctive qualities of various ice cream flavours, they create a more cohesive and delightful eating experience. This partnership highlights the importance of considering both taste and texture in product development, ultimately delivering a superior and more satisfying product to the consumer’, suggested Manoj.

Siddhartha admitted, “Generally, cones do not have any strong flavour as it can interfere or clash with the flavour of the ice cream. However, we use vanillin and create cones in different colours to enhance the visual appeal and overall taste experience of the ice cream.”

What technologies are utilized in the production of handmade cones and machine-made cones?

Sundeep informed that ideal cone production requires precise dosing of materials and baking at the correct temperature. This level of precision can only be achieved with automatic machine production. By utilizing automated machinery, manufacturers can ensure consistency in cone quality, achieving the perfect balance of texture and flavour in every batch.

“Automatic machine production allows for scrupulous control over the production process, ensuring that each cone is made to exact specifications. This precision is essential for maintaining the high standards expected by consumers and ensuring that the cones consistently complement and enhance the flavours of the ice cream they accompany”, Sundeep replied.

“We have high-capacity machines capable of producing cones with exceptional quality and speed. Our fully automated process ensures the highest standards of food safety for our customers’.

Raja PS further added, “We offer cones with aluminium sleeves customized with our customers’ branding and desired details about the ice cream. This minimizes the work required from our customers—they simply need to fill the cones with ice cream and seal them to complete the final product. Additionally, our innovative packaging style, which includes the cones with fitted sleeves, significantly reduces product damage by 99 pe cent.

“For machine-made cones, we utilize automatic machines with various capacities ranging from 7,500 cones per day to approximately 4,00,000 cones per day. In contrast, handmade cones are crafted in waffle baking machines manually, with a capacity of producing only about 1,500 cones in a day”, Manoj gave a frank reply.

Siddhartha explains, “In the production of ice cream cones, different technologies are used for handmade and machine-made cones:

Handmade Cones

Waffle Irons: For baking the cone batter into thin waffles.

Cone Rollers: Manual tools to shape the baked waffles into cones.

Temperature Control Systems: Ensure consistent baking temperature for even quality.

Quality Control Tools: Manual inspection tools for texture and shape consistency.

Machine-made Cones

Automated Baking Machines: High-capacity machines for consistent and efficient baking.

Shaping Machines: Automatically shape the baked batter into cones.

Cooling Systems: Rapid cooling to maintain shape and crispness.

Quality Control Software: Monitors and ensures consistent quality and safety standards.

These technologies help us produce high-quality cones efficiently and consistently, whether they are handmade or machine-made.”

How do you ensure that your cones meet industry standards for quality and safety, regardless of whether they are handmade or machine-made?

“At Ether Corporation, every cone undergoes rigorous inspection to meet industry standards. We employ automated surveillance systems and manual monitoring to ensure the quality of each cone. Our standardized manufacturing processes prioritize hygiene and sanitation. Regular third-party audits maintain transparency and uphold our commitment to delivering safe and reliable products”, was a devoted reply by Kishan.

“Meeting industry standards for quality and safety is crucial,” Sundeep explained. “Ensuring the correct moisture content is essential for the shelf life of cones. Using preferred fats like coconut oil, which promotes a high shelf life, is also vital. Implementing a metal detection system ensures safety during cone production. Additionally, all ingredients and inputs must be rigorously tested for quality before production. High levels of automation are necessary to maintain hygiene by minimizing human contact. These stringent requirements and technologies are challenging to achieve with handmade cones, making machine-made cones a more reliable and consistent option”, stressed Sundeep.

Assuring production at Mano Products, Raja PS stated, “Our production chain is fully automated, minimizing human involvement to ensure efficiency and hygiene. Despite the low human intervention, all employees wear head caps, gloves, and masks to prevent any potential contamination. Thanks to our team’s diligent attention to safety and quality, our factory and products have been awarded the FSSAI certification”.

Manoj cleared indicated, “Our cones undergo rigorous quality control measures before reaching our customers. This includes moisture testing conducted five times throughout the day, with weight, height, and other dimensional checks performed every 10 minutes. Our manufacturing environment is maintained in a closed, air-conditioned setting to prevent contamination during production and packaging. Added to the above, each box of cones undergoes inspection using an X-ray machine—we are the only cone manufacturing company in India to have this capability, ensuring the highest standards of safety and quality”.

Siddhartha’s points highlight the rigorous processes involved in maintaining quality and safety standards for cones, regardless of whether they are handmade or machine-made. Stringent quality control measures, material testing, adherence to standards, audits, certifications, and customer feedback all play crucial roles in ensuring that the cones meet the required criteria. These practices not only guarantee the quality of the product but also ensure the safety of consumers who use them.

How does the price of ice cream cones influence consumers’ decisions when making a purchase?

“The price of ice cream cones significantly influences consumers’ purchasing decisions”, declared Kishan. “When choosing a cone, consumers consider affordability, perceived value, and complementarity with the ice cream flavour. Lower-priced cones attract budget-conscious buyers, while higher-priced cones may be perceived as offering better quality or indulgence. Ultimately, consumers weigh price alongside other factors (such as flavour and portion size) to make informed choices”.

“The price of ice cream cones significantly influences consumer purchasing decisions. In some regions, particularly in places like Gujarat, where companies sell pre-packed cones priced at Rs. 5 or Rs. 10, affordability becomes a key factor. However, these cones often struggle to meet market demand during peak seasons. It’s worth noting that while ice cream was once considered a luxury product, it has become more accessible, with prices comparable to those of tea”, referred Sundeep.

He also added that while ice cream cones may seem like a small-cost component, their quality can greatly impact the overall ice cream experience. A poorly made cone can detract from the enjoyment of the ice cream, while a high-quality cone enhances the taste and texture, contributing positively to the consumer’s perception of value. Therefore, while price is an important consideration, consumers also weigh the quality of the cone when making their purchasing decisions.

Raja PS states that the price of ice cream cones plays a significant role in consumers’ purchasing decisions. “At our cone manufacturing company, we understand that competitive pricing can attract both wholesale buyers and end consumers. We strive to offer high-quality cones at affordable prices, ensuring our clients can maximize their profit margins while delivering a great product to their customers.

“Consumers often associate the price with the perceived value and quality of the product. By maintaining a balance between cost and quality, we help our clients build trust and satisfaction among their customers. Our competitive pricing strategy not only makes our cones accessible to a broader market but also encourages repeat business and brand loyalty. Additionally, our efficient, automated production process allows us to keep costs low without compromising on the superior quality of our cones, providing excellent value for money”, Raja PS finalized his words.

Manoj concluded with precision, stating, “Since cone pricing typically accounts for only 5-15% of the total ice cream cost, it has minimal influence on customer purchase preferences.”

“The price of ice cream cones significantly influences consumer decisions, considering factors such as perceived value, budget constraints, competitive pricing, promotions, brand loyalty, and the perception of quality,” Siddhartha explained. “Consumers weigh these factors when determining whether to purchase an ice cream cone, ultimately seeking a balance between price and value that aligns with their preferences and circumstances.”

End Lines:

The rise of artisanal and gourmet ice cream has also led to innovative cone designs and flavours, such as gluten-free options, cones made from alternative flours, or those infused with unique ingredients like matcha or activated charcoal.

Aesthetically pleasing and Instagram-worthy ice cream cones have become a trend, driving foot traffic to ice cream shops. This visual appeal is crucial in the age of social media, where unique and photogenic food items can go viral.