“Scoops of Success: Mastering the Ice Cream Business”

By Chandra Kant Bhardwaj

Introduction

We are thrilled to introduce our newest initiative, “Scoops of Success: Mastering the Ice Cream Business,” a series curated by Mr. Chandra Kant Bhardwaj, a renowned ice cream expert and founder CEO of Global Ice Cream Consulting Pvt. Ltd. This series is designed for entrepreneurs, industry professionals, and students in dairy or food technology technical courses.

Purpose and Vision

The objective of this series is to equip our readers with a deep understanding of the ice cream industry, from the scientific fundamentals to the technical intricacies of ice cream manufacturing technology. Our goal is to lay a solid foundation of knowledge that enables the production of superior world-class quality ice cream. By delving into the chemistry and technology behind ice cream, we aim to foster innovation and elevate industry standards worldwide.

Series Overview

“Scoops of Success” is set to be a comprehensive guide through the complexities of the ice cream manufacturing process. This 12-part series will cover a range of critical topics, including:

• The Science Behind Ice Cream Making: Understanding the chemical and physical principles that create creamy, delightful ice cream.

• Ice Cream Manufacturing Technology: From Quality raw and packaging materials to complete manufacturing details for ice cream mix and its physicochemical properties.

• Operations and KPIs: Streamlining operations and setting key performance indicators to boost overall efficiencies.

• Quality Assurance: Establishing a robust quality assurance department to ensure every batch of ice cream meets high standards, including lab setup and procedures.

Special Editions

In addition to regular posts, the series will feature special editions that explore:

• Greenfield Projects: Insights into launching small to large-scale ice cream manufacturing plants and project Management.

• Profitability Enhancements: Strategies to increase margins and reduce waste.

• Product Innovations: Leveraging new technologies to create novel ice cream products.

• FSSAI Regulations and Legal Declarations: Navigating the regulatory landscape to ensure compliance and market readiness.

This Edition’s Focus:

The Science Behind Ice Cream

In our first edition, we delve into the fascinating world of ice cream science. This includes exploring how ingredients interact at the molecular level, how different freezing techniques affect texture, and the role of emulsifiers and stabilizers in crafting the perfect scoop.

Market Overview and Challenges

The ice cream industry in India is booming, with a market size of approximately INR 25,000 crore per annum and an annual growth rate of around 15%. Despite the dynamic growth, the industry faces challenges like qualitative technological advancement, increasing costs and profitability issues, supply chain complexities, and stringent food safety regulations.

Future Prospects

The future looks promising with opportunities for technological innovations, cost and efficiency optimizations, and market expansion into burgeoning urban areas. As the market is expected to double in size within 4 to 5 years, industry players need to focus on improving product quality, increasing production capacity, and investing in high-quality equipment that can sustain for alteast15 years.

The Science of Ice Cream: Understanding Its Chemistry and Physics

1.Introduction and definition

Ice cream isn’t just a beloved treat; it’s also a fascinating subject of scientific inquiry. The ice cream manufacturing technology involves principles of chemistry and physics. This article provides a detailed look into the science behind ice cream, from its basic composition to the complex processes that create its creamy, delightful texture.

Common Definition of Ice Cream

Ice cream is made from a mixture of milk, cream, sugar, and flavourings, typically churned during freezing to incorporate air and create a smooth, creamy texture. It often includes additional ingredients like fruits, chocolate, or nuts, and comes in various flavours. Ice cream is universally enjoyed in scoops, cones, or as part of more elaborate desserts.

Technical Definition of Ice Cream

Technically, ice cream is a frozen colloidal emulsion consisting of water, fat, proteins (mainly casein and whey), sugars, and air. It is stabilized and emulsified by various type of stabilizers and emulsifiers. The standard formulation typically includes at least 10% fat, 36% total solids, and 15% sugar. During production, the mixture undergoes several critical processes:

1. Pasteurization: The mix is pasteurized to eliminate pathogens and ensure safety.

2. Homogenization: This process breaks down fat molecules to ensure they are evenly distributed throughout the mix, preventing the fat from separating during freezing.

3. Rapid Cooling and Aeration: The mix is rapidly cooled and aerated to control the size of ice crystals and the incorporation of air (overrun). This step is crucial for achieving the right texture.

The process of freezing point depression, primarily influenced by sugars and fats, helps form a semi-solid structure that is ideal for consumption at temperatures between -12°C to -14°C .

Regulatory Standards

In regulatory terms, particularly in jurisdictions like India under the Food Safety and Standards Authority of India (FSSAI), ice cream must meet specific compositional standards concerning fat and total solids content and others. These standards ensure that all commercially sold ice cream maintains a consistent quality and safety level. Labelling requirements, as defined by FSSAI, also help consumers understand what they are consuming, especially concerning allergens and nutritional content.

The Science Behind Ice Cream Making

The making of ice cream is a scientific art that balances flavor development with physical and chemical processes:

• Freezing Point Depression: The addition of sugars and fats lowers the freezing point of the mix, preventing ice cream from hardening into a solid block. This process is critical for maintaining the creamy texture that can be easily scooped.

• Control of Ice Crystallization: Ice crystals are inevitable, but their size and distribution are controlled through the ingredients and the freezing process. Smaller ice crystals are ideal for a smoother texture, achieved by rapid freezing and regular agitation.

• Air Incorporation (Overrun): Air is not just a filler; it is integral to the texture and volume of the final product. The right amount of air makes ice cream light and fluffy, while too much air can make it icy and too dense.

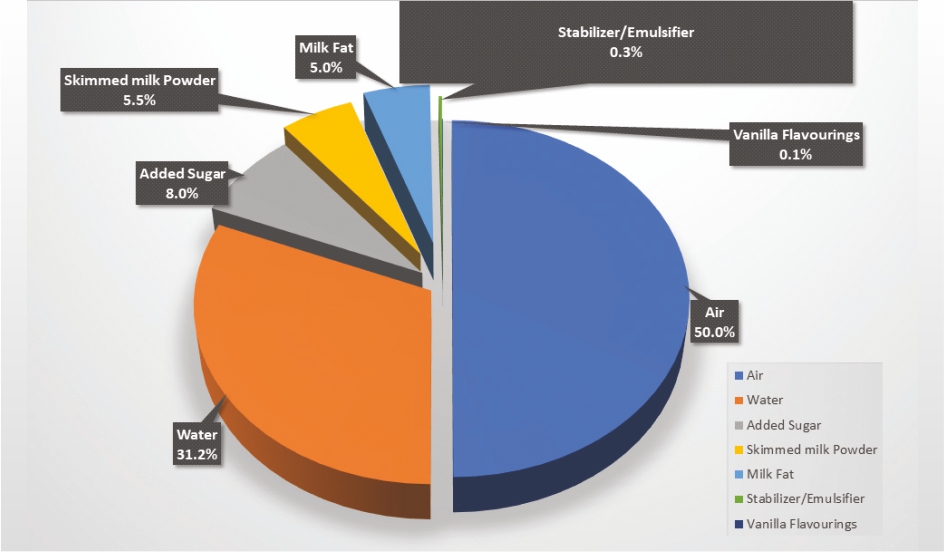

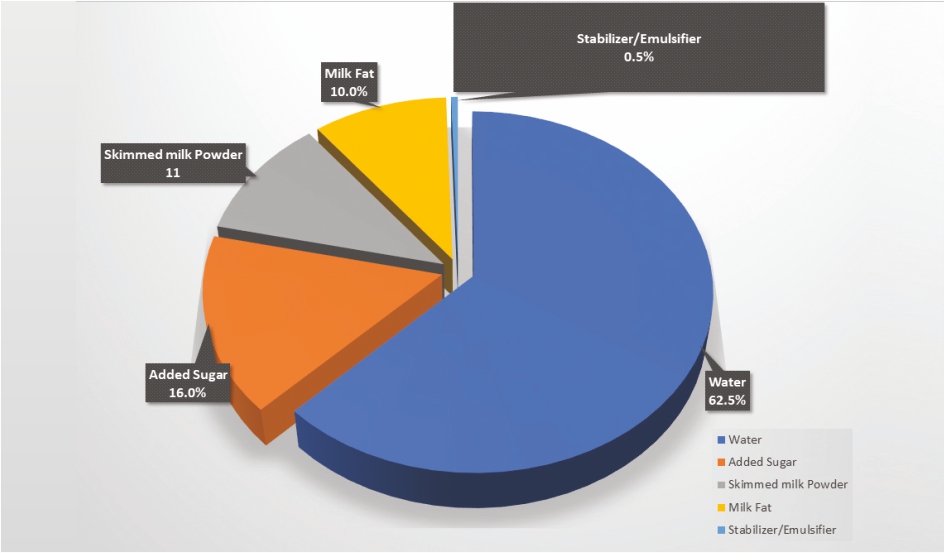

Composition of Vanilla Ice Cream mix at 100 % Overrun

Composition of Standard Ice Cream Mix

Ice cream is not just a popular dessert but a complex and scientifically fascinating food product. Understanding the detailed composition and science behind ice cream can enhance both its production and enjoyment. Here’s a closer look at the key components and how they contribute to ice cream’s delightful characteristics.

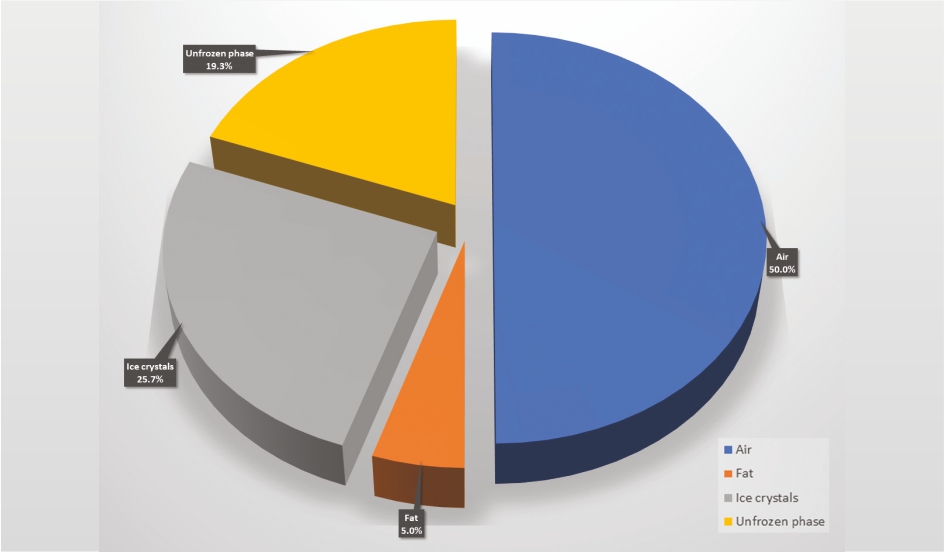

Phases in Ice Cream at -18°C

At -18°C, ice cream is typically in a semi-frozen state, showcasing distinct phases:

• Unfrozen Phase: Composed mainly of sugars, salts, and stabilizers dissolved in water, this phase remains unfrozen due to the depression of the freezing point by solutes. It contributes to the softness and scoopability of the ice cream.

• Frozen Phase: Consists mainly of ice crystals formed from water present in the mix.

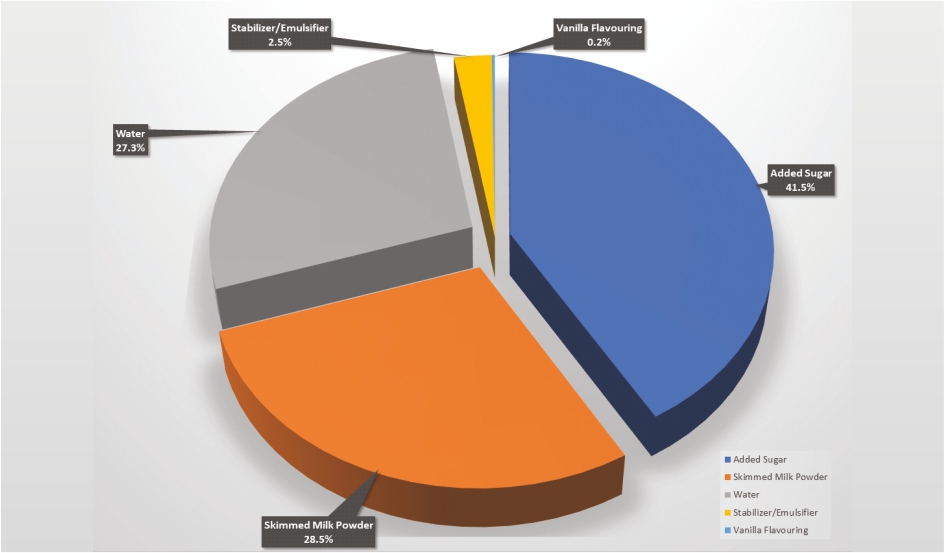

Composition of the Unfrozen Phase

The unfrozen phase is crucial for the textural properties of ice cream. It contains:

• High Concentration of Sugars: Helps in lowering the mixture’s overall freezing point.

• Stabilizers: Aid in maintaining the viscosity and preventing too much water from freezing, which in turn manages the size of the ice crystals.

2. Constituents of Ice Cream: A Comprehensive Breakdown

Ice cream is more than just a delightful treat; it’s a complex amalgamation of chemistry and culinary craft. Each component of ice cream plays a critical role in defining its taste, texture, and overall quality. Here’s an in-depth look at the key constituents of ice cream:

Fat

Fat is the cornerstone of ice cream’s creamy texture and rich flavor. Derived from dairy products such as cream or butterfat, fat is essential for:

• Enhancing Flavor: Fat is an excellent carrier for flavors, making them more pronounced and richer.

• Improving Texture: Fat coats the palate, offering a luxurious mouthfeel. It helps stabilize the air bubbles introduced during churning, contributing to ice cream’s smooth texture.

• Controlling Ice Formation: Fat disrupts the crystalline structure of water, preventing the formation of large ice crystals and keeping the ice cream soft and scoopable.

Non-Fat Milk Solids (NFMS)

Non-fat milk solids are indispensable in shaping the texture and enhancing the nutritional profile of

ice cream. They include proteins, lactose, minerals, and vitamins, contributing to:

• Texture and Body Enhancement: NFMS significantly improve the texture and body of ice cream, providing the necessary bulk and mouthfeel.

• Control of Ice Crystallization: Lactose in NFMS plays a critical role in managing ice crystallization, aiding in smoother texture.

• Flavor Enhancement: NFMS contribute essential dairy flavors intrinsic to ice cream’s characteristic taste.

• Nutritional Value: They enhance the nutritional content, adding proteins, minerals, and vitamins.

• Melting Resistance: NFMS also contribute to the melting resistance, ensuring the ice cream melts desirably when eaten.

Sugar

Sugar is vital not just for sweetness but also for its functional properties in ice cream:

• Lower Freezing Point: By lowering the freezing point, sugar ensures that ice cream remains soft and creamy, even at freezing temperatures.

• Body and Texture: Sugar increases the viscosity of the mix, aiding in the suppression of large ice crystals, thus ensuring a smoother texture.

Air

Often overlooked, air is crucial in determining the texture and volume of ice cream:

• Lightens the Texture: Air makes ice cream lighter and fluffier, enhancing its palatability.

• Increases Volume: Known as overrun, the incorporation of air during churning increases the volume of ice cream, influencing its creaminess and mouthfeel.

• Insulation: Air helps maintain a consistent texture and temperature throughout the ice cream, acting as an insulator.

Stabilizers

Ingredients like guar gum, carrageenan, and xanthan gum and others serve multiple roles:

• Prevent Ice Crystal Formation: They manage the water content effectively, reducing the formation and growth of ice crystals.

• Improve Creaminess: Stabilizers enhance the mix’s viscosity, contributing to a creamier and more cohesive body.

• Enhance Stability: Stabilizers help ice cream maintain its shape and resist melting, preserving quality during storage and transportation.

Emulsifiers

Emulsifiers such as Mono and Di Glycerides are crucial for integrating fat and water-based ingredients:

• Mix Fat and Water: They ensure that fat is evenly distributed within the ice cream, preventing separation.

• Stabilize Air Bubbles: Emulsifiers help stabilize the air bubbles introduced during churning, contributing to a uniform and stable texture.

Conclusion

Understanding the role and function of each constituent in ice cream is crucial for anyone involved in its production, from industrial manufacturers to artisanal creators. This knowledge not only aids in producing superior quality ice cream but also allows for innovation and improvement in recipes and production techniques. As we continue to explore the science behind ice cream in our series, we aim to enhance both the craft and the enjoyment of this beloved dessert.

To be continued…….