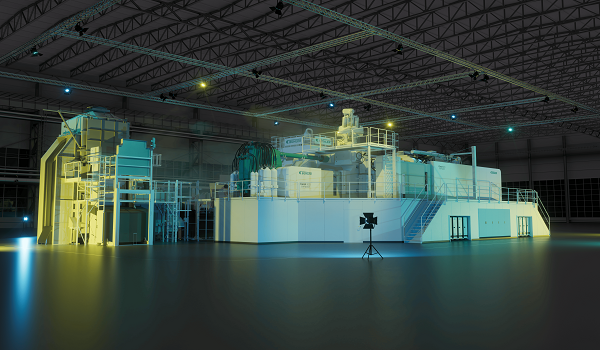

Bühler Group has reached a new milestone with the order of its 50th Carat megacasting solution, underscoring its role as a key enabler of megacasting for large structural components in the automotive industry. Six of the world’s top 10 carmakers have embraced the technology – four of them have placed orders with Bühler. Launched in 2020, Bühler’s megacasting series is experiencing growing demand as carmakers invest in more efficient production processes to meet the requirements of next-generation vehicles.

Bühler’s journey into megacasting began when the technology was still emerging. Early on, the company recognized that the rise of e-mobility was reshaping automotive production, including how the basic structure of vehicles would be manufactured. This shift opened new opportunities to simplify assembly complexity and to reduce weight, both critical factors in vehicle efficiency and manufacturing costs. Bühler, therefore, began developing solutions to support this transformation.

As megacasting reshapes the industry, global carmakers are accelerating it’s adoption and rethinking their manufacturing strategies. Currently, six of the world’s top 10 carmakers have embraced megacasting technologies – four of which have placed orders with Bühler. Carmakers such as Volvo and Honda, and suppliers to Original Equipment Manufacturers (OEMs), including Duoli Technology, Albert Handtmann Metallgusswerk, and GF Casting Solutions, have integrated Bühler Carat megacasting solutions into their operations to produce large structural parts for electric vehicles. Bühler’s megacasting installations are in operation across the globe, from North America to Europe and Asia.

“The order of our 50th Carat megacasting solution is a major milestone that reflects how far this technology has come – from a bold, almost experimental concept to a transformative force in automotive production,” says Cornel Mendler, Managing Director Die Casting at Bühler. “Major carmakers around the world have committed to megacasting, and many have chosen Bühler as their trusted partner. This achievement is the result of long-term partnerships and our commitment to delivering reliable technology and comprehensive support.”

Well-positioned to lead development

With almost 100 years of die-casting experience and more than 30 years of leadership in die casting large parts, Bühler was well-positioned to play a key role in the development of the new megacasting technology and support its customers in capitalizing on the revolutionary new trend. In response, the company launched 50,000+ kilonewton (kN) megacasting solutions, starting with the Carat 560 and 610 in 2020, and the Carat 840 and 920 in 2021.

Megacasting enables the production of large, single-piece components such as front or rear underbodies and battery housings by replacing the assembly of 50 to 100 smaller parts. This approach simplifies manufacturing, reduces vehicle weight, and improves structural performance. With fewer joining processes and less material waste, megacasting also supports more sustainable production. This approach is independent of the drivetrain, making it suitable for both traditional and electric vehicle architectures. Bühler’s Carat series, designed specifically for megacasting, offers die locking forces up to 92,000 kN to meet the demands of modern automotive platforms.

Supporting customers entering the megacasting market

For many manufacturers, adopting megacasting means implementing new production strategies – often at greenfield or brownfield sites, with teams that are new to large-part die casting. Bühler supports customers from the earliest stages, contributing to part design, cell engineering, and guiding process optimization tailored to the unique demands of megacasting.

“We work closely with customers to ensure a successful start in megacasting,” says Martin Lagler, Director Global Application Technology Die Casting at Bühler Die Casting. “That begins with part design and continues through team training and production start-up. Our involvement spans the full project life cycle – helping customers improve processes, solve challenges, and meet their quality and efficiency targets.”

Bühler’s global team of application and process specialists provides ongoing support as production scales, offering hands-on expertise, troubleshooting, and continuous improvement. This comprehensive support is key in helping customers succeed with megacasting, particularly as they scale up new processes and facilities.

Reliable performance, lasting value

As megacasting scales up, manufacturers must manage not only complexity but also cost efficiency, including uptime and yield. Bühler’s approach addresses these operational priorities through equipment designed for availability, durability, and long-term value.

“Our equipment delivers consistently high availability and low scrap rates – critical factors in productivity and profitability,” says Michael Cinelli, Director of Product Management, Die Casting at Bühler. “This focus on performance goes hand in hand with durability, as many of our die-casting machines have been in continuous operation for more than 20 years, which speaks volumes about their high-quality design.”

This long equipment life cycle is the result of Bühler’s engineering philosophy, focused on longevity and reliability. The same principles are applied to Bühler’s megacasting solutions, which are built for lasting use and upgradability. Older systems can be brought up to the latest standards and returned to service with like-new performance. This long equipment life cycle helps customers lower operating expenses while reducing the environmental and capital costs of replacement.

Bühler’s global service network and life cycle support – including upgrades, spare parts, and process optimization – further enhance productivity, helping customers reduce downtime and operate with greater efficiency.

Global presence, local expertise

Bühler operates with a global manufacturing and service footprint, enabling it to deliver megacasting solutions close to customer sites. With production, sales, and support hubs in Europe, China, and the US, the company provides responsive, localized service while maintaining global standards. These regional hubs coordinate manufacturing, project execution, service, and spare parts support, helping customers and ramp up production.

“With Bühler, customers minimize risk and build future readiness,” says Cornel Mendler. “We have global manufacturing and service capabilities – with a presence in all major automotive markets, where we communicate in our customers’ languages and understand their business cultures. Our three-hub structure ensures comprehensive support, from initial project execution to lifelong service, upgrades, and remanufacturing.”

Looking ahead

With almost 1,000 Carat machines in operation worldwide, and nearly 100 years of experience in die casting, Bühler provides a strong foundation for the continued development of megacasting. The order of the 50th megacasting solution reflects Bühler’s ongoing role in supporting automotive manufacturers as they scale up future vehicle production and adopt new manufacturing strategies.

“Megacasting is driving a broader transformation in automotive production, and we will continue to invest in the technologies, expertise, and partnerships that help our customers succeed,” says Mendler. “Every new project is a chance to push boundaries, support our customers, and drive the industry forward. The innovation potential is enormous.”